Charlie Peckar creates designer tap handles and other beer accoutrements is at Green Mountain Taps in Hinsdale, New Hampshire.

Since joining Green Mountain Taps in 2015, 3D designer Charlie Peckar has worked with 700 breweries. With nearly 5,000 craft breweries in the United States and draft culture growing, it’s likely Peckar will see that number continue to grow. Green Mountain offers designer tap handles as unique as the brews themselves.

Peckar cites both an expertise with wood and their U.S. factory location in Hinsdale, New Hampshire (the business was founded in Guilford, Vermont, and later moved across the river) as two reasons for Green Mountain’s success. “Most of our competitors source all their labor to China. We are the only company that makes 100 percent of our product in America,” he says. Craft brewers of New England, whose beverages and brands often trade on the importance of local production, find a kindred spirit in Green Mountain. The proof is in the pints: “We make pretty much all of the tap handles for the state of Vermont. We do Zero Gravity, 14th Star, Lawson’s. . .”

It doesn’t end with tap handles. “We do signage, we can source printed glassware. . .The idea is to be the one-stop shop for brewery needs.”

At McNeill’s brewery in Brattleboro, Vermont, shiny wooden tasting trays that Peckar designed sit in a stack behind the bar. “I was proud of that design. Not quite as ergonomic as I had planned, but I think they look pretty good.” Stumbling upon his work is common. Gigging around Vermont with his “folkgrass” band Pinedrop, Peckar often runs into handles he conceived.

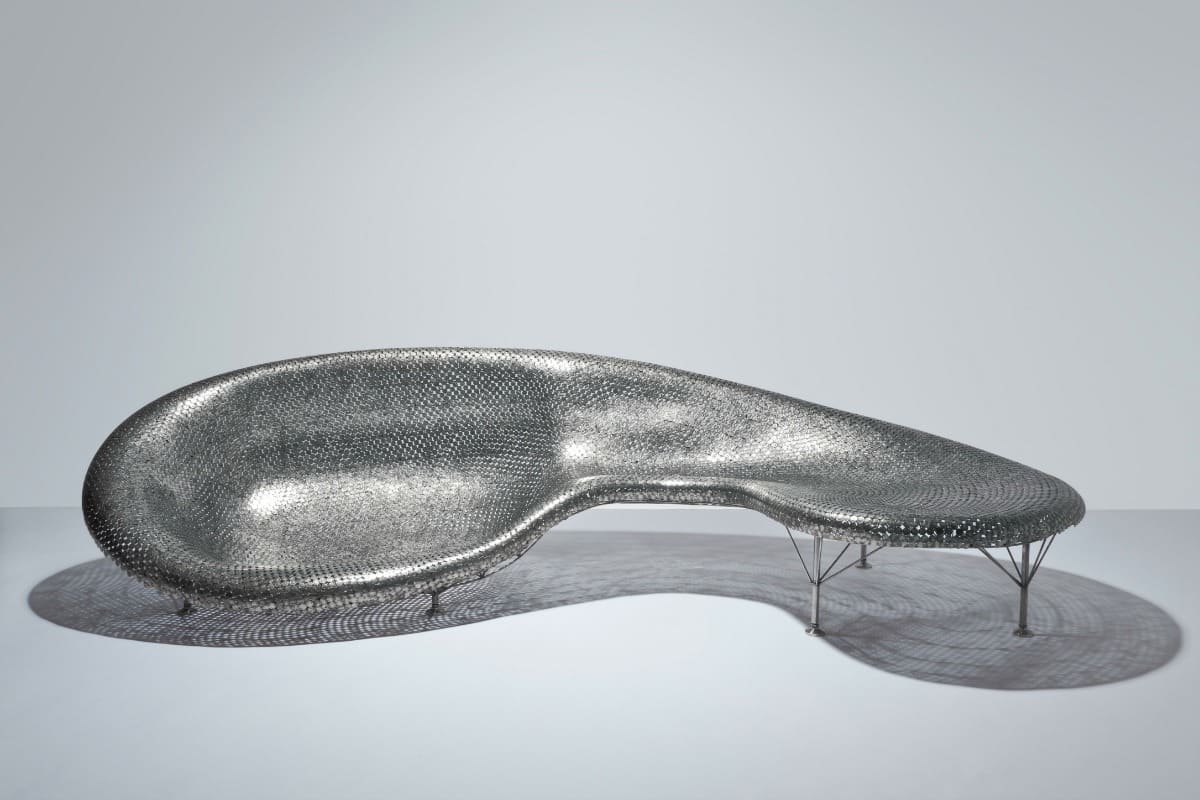

Green Mountain Taps creates more than designer tap handles. Custom flight set anyone? | Photo by Charlie Peckar

What is work for a 3D designer? For Peckar, it’s overseeing a piece as it evolves from initial client call, through a computer rendering, and out to a finished product. “I’ve got all the assets for production. All the shapes and models and plans come from me.” Just like beer, custom tap handles are a scientific art. Peckar, who focused on glassblowing in college, “picked up almost all of it on the fly.”

Once hired, “I learned CAD software and how to use all of the machines that we work with.” Depending on client needs, the Green Mountain production team will use 3D printers, metalwork, lasers, and more to make a tap. Custom designs require willingness: “We will work around any idea. We’ve used things like tiny bells and rope. Some things have been welded together.”

Though the process is complex, and few handles alike, Peckar jokes that the mechanics lead to one place: “They all kinda work the same way. They screw onto the tap, and you pull.”